Rotary Screen Engraving

Art & Art Work Prep

Once a pattern has been selected for engraving, our design team will prepare it for engraving. The first step is cleaning up the pattern so the boundaries between colors are defined. We work with the client to select pattern size, scale, and resolution. Adjoining colors are then trapped to each other to ensure there are no gaps between colors during printing. Color absorption into the fabric is also accounted for. Finally, the colors are separated into different files and sent to the engraving machine for screen engraving.

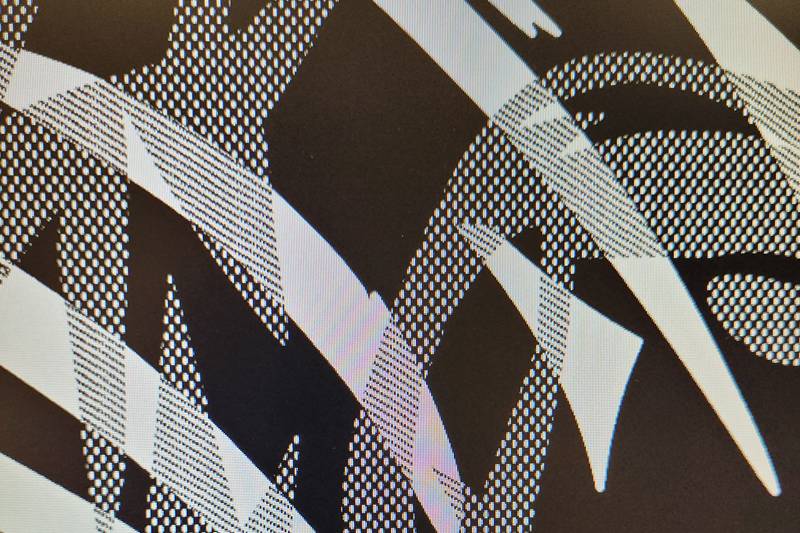

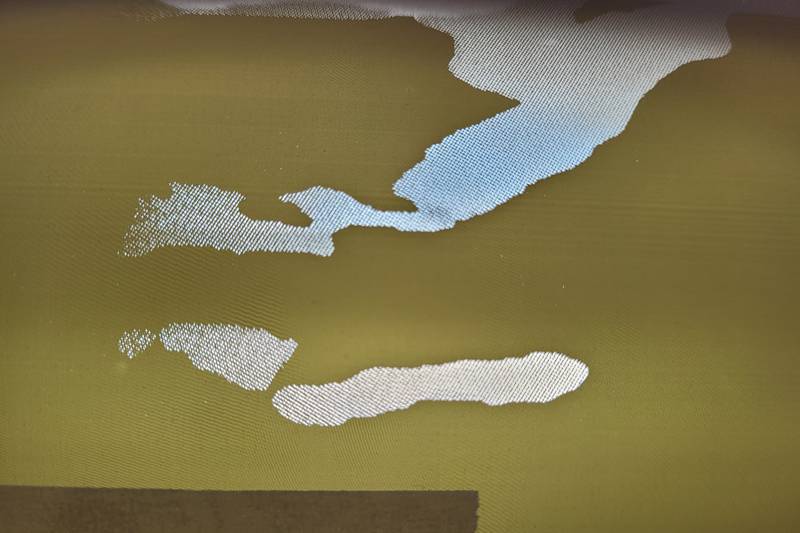

SCREEN ENGRAVING

Once the pattern has been prepared for engraving, our engraver will select the appropriate screens required for rotary screen printing and then engrave them using one of our two Stork laser engraving machines. We stock all the standard screen diameters (25.25", 27", 32" 36"), mesh sizes (30, 60, 80, 105, 125, 155, 195), and end ring types (Stork and Zimmer). We prepare our screens for engraving, so we always have a screen in stock and ready for engraving, no matter how unique your need is. After engraving, we install the appropriate end rings for the printer you selected, ensuring they all align properly, and that's it. Your screens are ready for printing. We offer free delivery to any of the printers in the Los Angeles area, or we can ship your screens nationwide.

For further information, feel free to get in touch with us.